STOP FIGHTING FIRES. START PROTECTING YOUR UPTIME.

If you’re reacting to unexpected forklift failures, chasing down service vendors, or holding your breath during each inspection, you’re not alone. When warehouse and operations managers get stuck in a cycle of reactive maintenance, it costs them time, money, and trust with leadership. Planned Maintenance (PM) is how you break that cycle. With Equipment Depot, you get access to a proactive PM program led by expert technicians that catches problems before they shut you down. All of which helps you stay focused on your operation instead of on equipment issues.

MAINTAIN

WARRANTY STATUS

Keep your factory warranties valid with regular maintenance performed by certified technicians

LIMIT MAJOR

REPAIRS

Address minor issues before they develop into costly major repairs, saving you significant maintenance costs

MINIMIZE

DOWNTIME

Stay ahead of failures and reduce unexpected breakdowns and disruptions to your operation

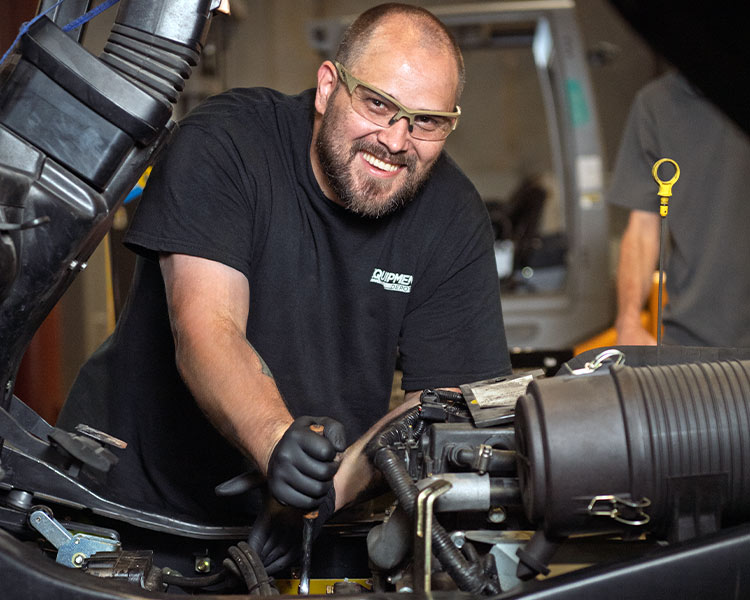

EXPERT PLANNED MAINTENANCE PROGRAMS FOR FORKLIFTS

Whether you have one forklift in your building or an entire fleet of lift trucks, you can ensure that your equipment operates at peak performance by enrolling in a planned maintenance (PM) program with Equipment Depot. Instead of waiting for something to break, we help you stay ahead of wear and tear by inspecting, servicing, and replacing parts at the right time, before you experience unexpected downtime.

BENEFITS OF PLANNED MAINTENANCE

Our maintenance programs are built around a consistent schedule of visits based on OEM recommendations, equipment usage, our technicians’ expert knowledge, and real-world service data. Every PM visit includes detailed inspections, adjustments, and a recommended list of any repairs or component replacements to keep your fleet compliant, safe, and ready to perform.

REDUCE DOWNTIME

Catch issues before they turn into breakdowns. Planned maintenance helps limit unexpected forklift failures that interrupt your operation and slow down throughput.

PROTECT FACTORY WARRANTIES

When you invest in new equipment, most OEMs require routine service on a set schedule to keep any warranties valid. Miss a service or fail to document it properly and you risk voiding coverage when you need it the most. With our PM program, we follow OEM guidelines to the letter and document each visit, ensuring you’re always in compliance and protected from costly claim denials.

LOWER REPAIR COSTS

Routine service extends equipment life and reduces the risk of expensive emergency repairs or rush orders on replacement parts.

IMPROVE SAFETY & COMPLIANCE

Avoid OSHA violations and unsafe conditions with regular inspections. Our techs check everything – brakes, hydraulics, steering, lights – to help you create a safe work environment and protect your employees.

MAXIMIZE LIFESPAN

Well-maintained equipment stays in your fleet longer, works better, and delivers more ROI across its lifecycle.

BUDGET PREDICTABILITY

With less surprises, your equipment maintenance becomes a more controlled operating expense. Not an unpredictable emergency.

WHAT’S INCLUDED IN A

PLANNED MAINTENANCE VISIT?

Every PM visit is structured, logged, and executed by your assigned technician, so nothing gets missed and you know exactly what was done. Here’s what we include in a typical visit:

GET SERVICE

WHY CHOOSE EQUIPMENT DEPOT?

SAME TECH. A HIGHER STANDARD. EVERY TIME.

We assign you a dedicated technician who learns your equipment and facility, which means consistent service, reliable results, and less time spent getting a new technician familiar with your fleet.

THE SIMPLICITY OF A SINGLE VENDOR

No juggling multiple service providers. Our techs are trained to service all makes and models of forklifts, reach trucks, pallet jacks, turret trucks, order pickers, walkie stackers, end riders, boom lifts, telehandlers, scissor lifts, attachments, batteries, chargers, and more. Get everything covered in a single cohesive PM plan.

PROACTIVE COMMUNICATION

You’ll always know what’s coming. We schedule service around your operation and provide detailed reports and recommendations after each PM visit.

BUILT-IN FLEXIBILITY

Need to adjust maintenance intervals, add new units, or scale up your service? Our programs are customized to fit around your needs.

HEAR FROM

OUR CUSTOMERS

LET’S PROTECT YOUR UPTIME

Stop letting equipment issues take up your valuable time. Partner with our expert team to build a proactive plan that puts you back in control of your uptime and your budget. Get your custom Planned Maintenance quote today.

CONTACT US